The concept of 3D printing is so mind-bendingly futuristic it sounds like it belongs on the deck of the starship Enterprise. But it is being hailed as the vanguard of the Third Industrial Revolution – a democratising force allowing anyone with a relatively inexpensive machine to print anything from car parts to a new pair of shoes.

It basically involves converting a computer-generated image into a solid object through “sequential layering” – building your creation up through thousands upon thousands of microscopic horizontal layers. This can be done in several ways, most commonly by softening materials, or by hardening photosensitive liquids using UV light.

The process essentially inverts the type of sculpture you probably learnt at school, where you start with something big and carve away at it until it is the size you want (subtractive, as opposed to additive, manufacturing). One advantage of additive manufacturing is that you can build incredible detail into areas of an object that would be all but impossible to reach by other methods – you can even make items with moving parts.

Materials that can be manipulated include metal, salt, sugar, wood filament, cement, ceramics, carbon fibre, silicone and rubber. Anything that can be melted, sprayed or otherwise deposited in incremental layers can, in theory, be used in a 3D printer. State-of-the-art models such as the Stratasys Objet500 are able to print using multiple materials at the same time (although at US$330,000, it’s not for amateurs).

While the technology is still in its relative infancy – it emerged 30 years ago but only really took off in the past decade – its possible uses are intriguing. Printers are being developed for medical use – imagine the potential of printing replacement joints, or teeth, modelled to fit the dimensions of the recipient’s body.

Fashion designers have created entire dresses from it. Nokia has released schematics for home-printable cases for its Lumia smartphone range, while Rolls-Royce has spoken of plans for the 3D printing of jet- engine parts. Still, the technology has raised some legal and moral issues, not least surrounding the printing of guns – which have already been created and proven to work.

Desktop 3D printers are often used to create hand-held models but some are able to make objects as big as basketballs. Printing speeds vary, but larger items tend to take several hours or even days to complete.

While the cheapest models used to be in excess of US$3,000, they are now coming down to less than US$1,500. This will open up their functionality to small businesses, whose employees could take a printer to meetings to demonstrate new products to clients.

The machines are also shrinking – once the size of chest freezers, there are models in production that can fold into a briefcase. Here are some of the best, most innovative models around.

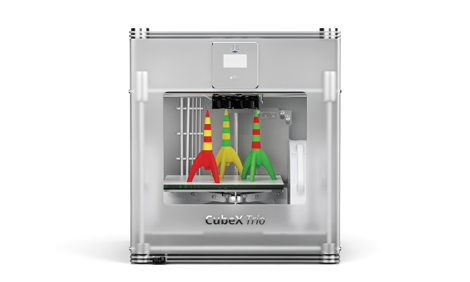

CubeX Trio

Build dimensions 18.5cm x 26.5cm x 24cm

PRICE US$4,399

PROS Prints different colours and materials

CONS Expensive

The Cubex Trio is one of the best-known desktop 3D printers. It is able to extrude different materials at the same time (ABS and PLA plastics), which sets it apart from many rivals. It can also print in three colours at once, significantly broadening the horizons of what you can create. Its resolution is not bad, at 100 microns, but not as good as some of its rivals.

FlashForge Creator II

Build dimensions 22.5cm x 14.5cm x 15cm

PRICE US$1,099

PROS Affordable and portable

CONS Single extruder

The Creator II is a single extruder device that prints at a respectable resolution (for the price) of 100 microns. It has a home-built aesthetic and is aimed more at the amateur enthusiast than the business professional. Having said that, it is relatively light (15kg), making it one of the more portable models. It prints using PLA/ABS plastics and uses open-source software that is free to download. If you’re new to 3D printing and want to try it out, this might be the one.

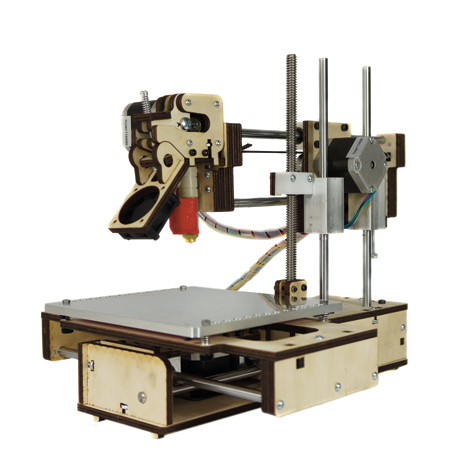

Printrbot Jr (v2)

Build dimensions 15cm x 15cm x 15cm

PRICE US$700(assembled)

PROS Good all-rounder

CONS Single colour

This may look like a child’s Meccano set – and a fairly lame one at that – but it is actually a very respectable gadget. Available either as a kit or ready assembled, the unit can fold, which makes transporting it far easier (it weighs 8.2kg). It is a good all-round option, with relatively quick print speeds, an enticing price tag and easy connectivity to your laptop via USB. At the moment it is not upgradable beyond a single reel of resin, meaning you can only print single-colour items.

Ultimaker 2

Build dimensions23cm x 22.5cm x 25cm

PRICE US$2,625

PROS Very fast

CONS Pricey, doesn’t work with wifi yet

The Ultimaker 2 is quite possibly the best 3D printer on the market right now. Its design is slick, it’s fast and has everything you need to start creating 3D objects. At the moment the device only supports single-colour printing, but this will be upgradable to two colours in the coming months. The final products are of excellent quality, with great detail even on tricky edges. It presently supports SD card or USB but, later this year, the unit will be compatible with wifi.

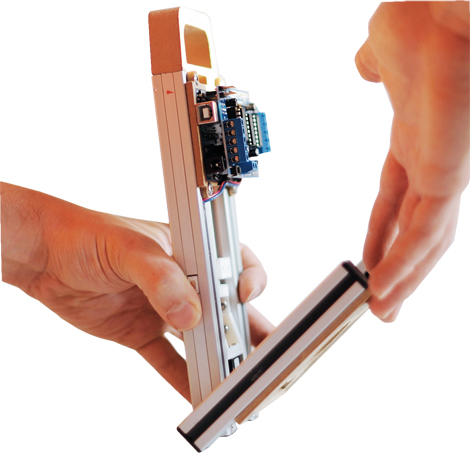

LumiFold foldable 3D printer

Build dimensions

9cm x 9cm x 9cm

PRICE US$400

PROS Tiny unit, nifty upgrades in development

CONS Small print area

The Lumifold is the smallest3D printer on the market (25cm x 12cm x 3cm), making it ideal for packing into a suitcase for roadshows or pitches. It employs a different process to most, using a projector (sold separately) to beam light on to photosensitive resin. This allows for detailed models, but it can print only small items such as miniature figurines. Clever add-ons include a HoloDock, which shows a 3D image of your model while it is being created.

MakerBot Replicator Mini

Build dimensions

10cm x 10cm x 12.5cm

PRICE US$1,375

PROS Attractive,

simple design

CONS Not the best resolution

In the 3D world, Makerbot is a big deal – it creates gadgets that look like Steve Jobs might have designed them. Its printers are known for their reliability and large prices. The Replicator Mini comes with wireless connectivity and cloud access, so you can beam your design files straight to the machine. The interface couldn’t be simpler – there is one “go” button, and the rest is done using the software. Its resolution isn’t as good as the larger Makerbot units, however, at 200 microns instead of 100.

CEL Robox

Build dimensions

21cm x 15cm x 10cm

PRICE US$1,423 (available June 2014)

PROS Fast speed

CONS Prints one material at a time

Ease of use is the biggest selling point of the Robox, which secured more than US$480,000 via crowd-funding site Kickstarter for its development. The unit works straight out of the box with no need for calibration. It prints at high resolution and uses a dual nozzle system, which makes it up to three times faster than some rivals. The reels of printing material are fitted with microchips, so the unit can detect when a new substance has been loaded. This means you don’t have to reprogram it when switching to a new colour or plastic.

Bukito Portable

Build dimensions

12.5cm x 15cm x 12.5cm

PRICE US$849

PROS Small, light

CONS Have to build it yourself

Another Kickstarter project, Deezmaker’s Bukito is small and light (2.7kg), making it great for travellers who need to give presentations overseas. It is bought in kit form, so will take a little patience and dedication to get it into fully working order, but its aluminium rails make it robust. It can print in one colour as standard, using PLA plastics, but may allow upgrades in the future, including the ability to print using nylon and laywood. Even better, this is one of the most reasonably priced models out there.

3D Printing Pen

Build dimensions

Unlimited

PRICE US$116

PROS Cheap, tiny

CONS Final product is not professional-grade

The Printing Pen is a completely different experience from any other 3D printer out there. It is essentially an unanchored nozzle, which you can use to extrude your PLA plastic in any shape you want. The final products look a little bit like they’re made from spaghetti, but it’s great fun, and any object that can support its own weight during construction is theoretically possible to craft. It is also cheaper than any other 3D printers by a mile.

MakerBot DigitiZer

Scan dimensions

20.3cm x 20.3cm x 20.3cm

PRICE US$799

PROS Compact, fast

CONS New tech, so not perfect results

Most of the products you will print using today’s crop of 3D printers will come through computer aided design (CAD) files. However, consumer-level 3D scanning technology is already available and is getting better all the time. The Makerbot Digitizer is one of the better ones, being able to scan items using a compact turntable (you can easily fit one in a suitcase) and turn them into files that will work with most 3D printers. It takes about 12 minutes to scan an object, and you can then print yourself a new one whenever you like.