Cathay Pacific Catering Services (CPCS), a wholly-owned subsidiary of Cathay Pacific Airways, held a behind-the-scenes event yesterday showcasing its in-flight catering facilities and processess.

The catering unit, located next to Hong Kong International Airport, produces an average of 81,100 meals every day for 43 international airlines operating 196 daily flights.

CPCS chief executive Jenny Lam explained that the current maximum capacity is 100,000 meals per day, but this is set to grow, with a new catering facility currently in development. Once completed later this year, food production output will be boosted by up to 40 per cent, allowing CPCS to keep up with ever-increasing travel demarnds.

Business Traveller Asia-Pacific visited the CPCS facility. Here are the highlights.

Employees and visitors entering the food production areas of CPCS are required to wear lab coats, face masks and head caps at all times.

Stringent hygiene protocols

Several hygiene safety areas are located near the entrance, where there are sinks to wash your hands, alcohol cleanser dispensers and adhesive rollers to remove dust and hair from clothing.

Decanting area

Perishables such as vegetables are first taken to the decanting area, where they are moved from boxes into crates, before being transported to a processing room. According to CPCS, this helps to preserve the freshness of the ingredients and ensure any pests in the containers are separated from the food.

Vegetable washing process

A vegetable processing room is located further ahead where the greens are thoroughly washed in a “Jacuzzi-type” bath. The water’s turbulence helps to separate impurities and grubs from the ingredients. Interestingly, only vegetables served in first and business class are washed and processed at CPCS, while the greens served in economy are processed at an external facility before being transported to CPCS for cooking.

Fruit preparation area

Opposite the vegetable processing area is a room where fruit is prepared. CPCS handles some 12,000kg of fruit per day, with watermelons representing half of this. Philip Tung, commercial manager of CPCS, explained this was because the fruit retains its sweetness regardless of the season and is a popular choice with customers.

A CPCS employee shapes a tray of croissants

Up next was the bakery, where CPCS produces over 90 per cent of all bread served on board. This includes everything from the rolls served in economy to the croissants and garlic bread in first and business.

Mixing large quantities of flour and yeast

Bread mixing machines churn yeast and flour throughout the day. In another section of the bakery, this bread mixture is then shaped and baked in one of the many ovens.

A batch of freshly baked croissants

Industrial-grade convection ovens are able to bake multiple batches of bread via precise temperature controls.

Halal food preparation

In the halal foods cooking area, the smell of aromatic spices being mixed up in a batch of curry is enticing. This section of the facility is completely devoid of pork, while cookery equipment and utensils used here are specially marked and washed separately from those in other parts of the complex.

Roughly 3,800 to 4,000 special meals are prepared daily, with Cathay Pacific offering 21 different varieties. Special meals can be prepared with a minimum of 24 hours' notice.

In the next area, the cooked vegetables are loaded into serving dishes…

… along with sandwich buns being filled with meat and cheese…

… while CPCS cooks select raspberries to add to cakes.

Deep frying helps ingredients retain moisture better

The main cooking area is the single biggest area in the facility.

Separated into Chinese and Western food sections, the former features several wok stations where cooks deep-fry seafood. Whilst deep frying may not be the healthiest option, Tung revealed that this method of cooking allows seafood and meat to retain moisture better.

Omelette station

Over in the Western cooking area is the egg station, which features a rotating conveyor belt with multiple frying pans. Oil and egg mixtures are added to each pan by automatic dispensers, with two cooks working around the line to cook and plate the eggs.

Plating the meals

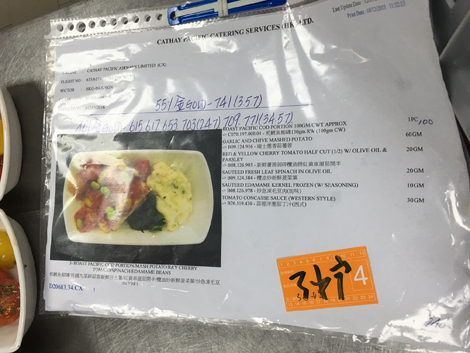

The final stop is the plating area, where the cooked ingredients are carefully placed together to produce the finished dish. This is done manually so staff can check that all ingredients are cooked well and have retained their shape and colour.

Data cards showcasing images of the finished dish help the cooks plate the food, and also contain information regarding the flight on which the dish will be served.

The finished dishes are then quickly transferred to cold storage, where the temperature is set to 10°C. They are usually stored overnight (and up to a maximum of 24 hours) before being transported and loaded onto the designated aircraft the next day.

For more information, visit cathaypacific.com

Clement Huang